The active thermal probe

Details

data mining

The figure below shows the applied heating power and the temperature of the sensor over time. [2]

Measurements were taken on an ion source (beam diameter 160 mm) at a distance of 225 mm, at a working pressure of 0.04 Pa and a beam voltage of 500 V.

After switching on the energy source (ion source) at approx. 300 s, the probe temperature rises, whereupon the controller reacts by reducing the heating power. After approx. 20 s the temperature equilibrium is restored. At this point, the heating power supplied to the probe is about 500 mW less than in the "plasma off" state, which corresponds to the energy influx arriving from the ion source. The time it takes for the temperature to reach equilibrium depends on the size of the change in the energy input. It ranges from a few seconds to a maximum of 20 seconds.

When used for process control, however, it is not necessary to wait for the temperature equilibrium to be set at the probe. Since the heating capacity of the sensor reacts to changes in the process parameters within a fraction of a second, a signal can be sent immediately to the process control. It is even possible to set up a further control circuit, so to speak, in which the heating output of the sensor is the controlled variable and the process parameters are the controlled variables.

Technical parameters

| description | Vacuum-compatible probe for in situ measurement of the energy input |

|---|---|

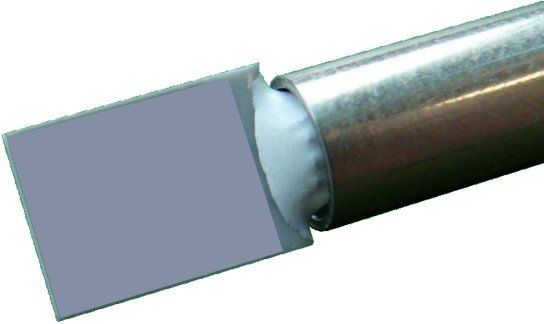

| mechanical properties | Ceramic sensor, chemically inert, thickness 0.7 mm |

| measuring range | 1 mW/cm² bis 2 W/cm² (im passive-Mode bis 100 W/cm²) |

| temperature range | Operational up to 400 °C, resistant up to 600 °C |

| measuring surface | 7 x 7 mm |

| probe dimensions | 15 mm x 170 mm Custom length and geometry possible |

| bias voltage | max. 500 V |

| weight | < 50 g without connecting cable |

| Sensitivity / Accuracy | 1 mW/cm² |

scope of delivery

The probe can be delivered in various versions, each of which can also be customized further.

The same applies to controlling the probe and the required service. You will find a list and description of all options and details here.

Scope of delivery standard:

| Probe with shaft and connector |

|---|

| Probe connection cable |

| Vacuum feedthrough on flange KF40 |

| Connection cable to the control unit |

| Supply and control unit with power pack and USB cable |

| Basic software for setting up and operating the probe |